The ecommerce landscape has shifted significantly in the last ten years. Along with this, the demand for product packaging solutions that can manage shipping and logistics, as well as create a unique customer touchpoint, has also grown. By 2025, the total market value for these solutions is expected to reach $61.55 billion dollars.

Product packaging is sort of like makeup for your product. It’s there to make it look good and presentable for when you’re trying to sell it. And, similar to how you wouldn’t buy a product from a store if it were just thrown haphazardly onto a shelf, consumers are less likely to buy your product if it doesn’t look like it was put together with care.

The process of designing, evaluating and producing product packaging can greatly impact a company’s profitability and customer satisfaction. Many online retailers create branded product packaging experiences to improve the customer experience and bottom line.

According to a study by The Paperworker, about 52% of online consumers would most likely return to a business if they received their product in high-quality packaging. So not only does your product’s packaging act as an important first impression, but it can also affect customer loyalty. Additionally, 74% of consumers will most likely share a photo of product packaging to their social media. So not only will good packaging help you make sales, but it’ll also help you gain free marketing from your customers.

As you can see, an effective product packaging design can create tons of leverage for your business.

So you have this great new packaging idea, but you have no idea how to bring it to life? There are a lot of factors to take into consideration, but lucky for you, we have a comprehensive guide that will take you through every step of the process in the simplest way possible.

1. Considerations Before Product Packaging Design

Before getting started with the process, it’s important to take a step back and assess your product packaging needs. This will help you determine what your options are, what the production and shipping costs might be, and what the best solution for your product might be. Once you have a better understanding of all of these factors, you’ll be in a much better position to move forward with the packaging process.

Product

The type of packaging you’ll need will depend on your product’s size, shape, and weight. If your product is fragile, you’ll want packaging with more structure and cushioning. If it’s heavy, you’ll need packaging that can support it during shipping and/or distribution.

Volume of Packaging

You should make a note of how many units you will need, as this will directly affect your costs and business requirements. It is best to only order the amount that you actually need, in order to meet sustainability responsibilities and have a smooth supply chain process. Compare your sales and demand to determine the optimal volume for your packaging supply.

Budget

The budget for your product should include the cost of packaging, production and shipping. If you need packaging fillers, account for that in your budget as well. Make sure you are efficient with your budget and leave enough wiggle room for shipping cost changes. You can minimize costs by being efficient with your budget.

2. Measuring Packaging

The dimensions of a box are very important for several reasons. They affect the amount of materials needed, the production cost, and the shipping cost. Make sure to take all of these factors into account when deciding on box dimensions!

There are three key dimensions that all boxes are measured by: length, width, and depth. It’s critical that these measurements are always taken from the inside of the box and not the outside. Something as seemingly straightforward as measuring your box can have a major impact on the rest of your packaging process, so it’s important to be as accurate as possible from the start. And when you’re determining your dimensions, keep in mind that it’s usually best to err on the side of caution and make your box a little smaller rather than too large. Not only will this help your product fit snugly and avoid damage during transport, but it will also do your part to reduce your carbon footprint.

3. Finding your types of Product Packaging

There are many different types of product packaging, and each has its own advantages and disadvantages. The most common types of packaging are cardboard boxes, paper bags, and glass jars.

Folding Boxes

Folding Boxes is a great option for those looking for a light and flexible paper material (FREE DESIGN ONLINE HERE). It is also cost-effective, making it a great choice for a variety of projects. Folding carton is available in a variety of options, including raw kraft, solid bleached kraft (SBS), clay coated board (CCNB), white kraft, and black kraft.

Corrugated Boxes

Corrugated packaging is a tough and reliable option that is mostly used for strong products and shipping.

This type of fiberboard provides durability, padding, and ideal reinforcement for products – especially those in the eCommerce industry.

Paper bags

Paper bags packaging is used for a variety of purposes. It can be used to store and transport food, as well as other items. Paper bags are also commonly used as gift bags. They are often decorated with designs or messages, and can be personalized with the recipient’s name. Paper bags are a popular choice for packaging because they are inexpensive and easy to use.

The type of packaging you choose should be based on your product’s needs. For example, if your product is fragile, you will need to use stronger packaging to prevent it from breaking. If your product is perishable, you will need to use packaging that keeps it fresh. And if you are selling a product that is unique or eye-catching, you will want to use packaging that makes it stand out.

4. Understanding Packaging Printing Types

Once you’ve decided on the right packaging for your business, you’ll need to choose a printing method. Here are three printing options and the type of material they work best with:

Offset Printing

Offset printing is a printing method that uses ink instead of toner (digital printing), resulting in a higher quality image. It is typically used for mass production, as it can be more expensive for low-volume projects because it requires printing plates and additional setup fees. However, offset printing offers the ability to apply special processes during printing, which can improve the overall quality of the print job.

Digital Printing

The digital printing process is very similar to how your home office laser or inkjet printer works. The main benefits of digital printing are quicker turnaround times and affordability for low-volume jobs without any setup fees. However, the downside is that digital printing can’t quite match the color fidelity and material flexibility that offset printing offers.

Digital printing is available with folding carton and corrugated boxes. However, with new trends and innovations, “advances in digital printing for corrugated can now enable customization to be executed efficiently at scale,” according to Sara Dunn, of NAPCO Media.

Flexography Printing

Flexography printing is a type of industrial printing that uses simple structures and is best for printing one or two colors. The colors aren’t as vibrant and crisp as with other methods, but flexography is inexpensive, doesn’t require a lot of attention to detail, and can be produced at very high speed.

5. Colors in Printing

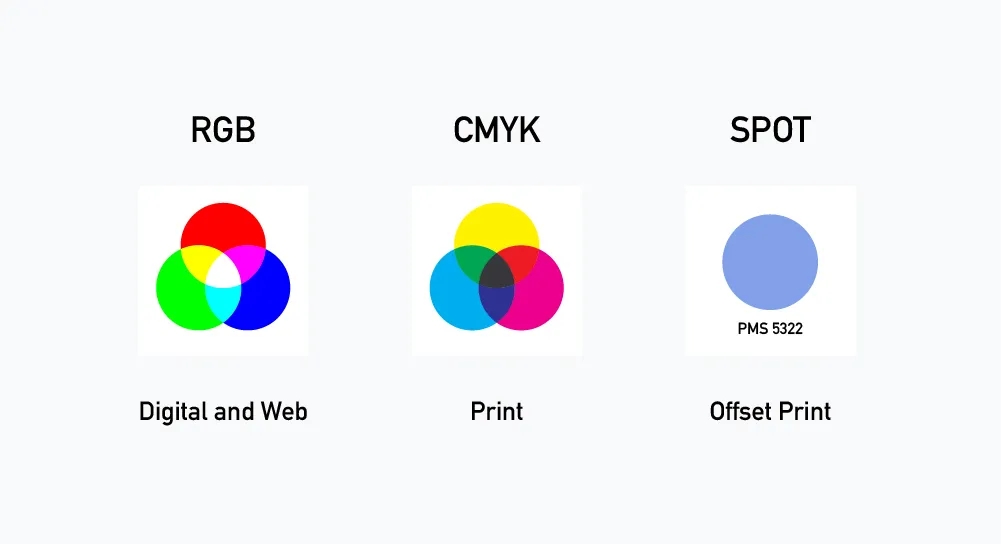

CMYK, also known as Cyan, Magenta, Yellow, and Key (Black), is the default color mode for printing. This process allows for an unlimited number of color combinations and possibilities in your artwork.

When working in Adobe Illustrator or Photoshop, using CMYK color mode will give you a more accurate color appearance when printing on paper. Therefore, it is highly recommended that designers do not work in RGB color mode.

PMS, or Pantone Matching System, is a standardized color matching system created by Pantone Inc. It is often used for branding purposes because it creates a uniform color code and allows for a wider range of colors to be printed with high consistency. However, PMS typically requires an additional cost for production.

6. Finding a Coating

A coating can be applied to complete the look while offering additional packaging protection and enhancement to the print quality.

There are two types of lamination: matte and gloss. Matte has no sheen while gloss provides a very impactful shine.

If you’re looking for a clear coating that is both quick-drying and environmentally friendly, AQ (aqueous) coating is a great option. This type of coating is often used on food, household, and other fast-consuming products. Unlike UV coating and lamination, AQ coating has a very faint gloss finish.

UV Coating can help you achieve a look similar to lamination, but with the added bonus of being able to apply it directly to your material (without needing additional film like lamination).

Varnish is a type of coating that is less expensive than other types of coatings, but it is also not as durable. It can be used to create a matte, gloss or other types of finishes.

Specialty coatings like metallic, pearlescent, and soft-touch (velvet) are becoming increasingly popular for brands looking to create unique and impactful packaging designs. These coatings can help your packaging stand out from the competition and give your products a luxurious look and feel.

7. Exploring Special Finishes

There are a few special processes you can use to enhance your packaging and make it more eye-catching. One of these is foil stamping. This process can help create a distinct look for your packaging. Foil stamping can add a touch of luxury to your project with its metallic, matte, gloss, holographic or special effects.

Spot UV can be used to highlight specific areas of your packaging, such as logos or artwork.

Embossing is a printing technique that adds dimension and depth to your packaging. It is accomplished by pressing text or an image into the card stock or paper. Embossing is commonly used to create impactful logo designs or product names.

Debossing creates a depressed imprint on card stock or paper surfaces and can be used to achieve a similar effect to embossing.

If you have an eye-catching product, window patching can be added to your packaging to display it prominently!

A die-cut window is added to your packaging so customers can see your product before making a purchase.

8. Packaging Design

Good design is important to drawing attention and evoking a positive consumer response. Pacdora offers 3D rendering and dieline & mockup edit online with all types of format to download. You can try it out online now.

If you don’t have a designer on hand, it is also advisable to work with a manufacturer or solution provider that can provide packaging & structural design services to streamline the process and get your packaging done more efficiently.

9. Preparing Dielines

Now that you have your design in place and are looking to get it transferred over to the structure template, a.k.a the dieline, there are a few things that your designated designer will need to take note of. Even if your artwork is completed and ready to go, there are still some requirements when it comes to preparing the dieline and artwork. By being aware of these requirements beforehand, you can help ensure a smoother and quicker design process. Check out our dieline articles.

A dieline is a tool that helps you understand the orientation of your packaging design. It is important to be precise with the measurements and specifications to save time and money. The dieline acts as a flat blueprint for your packaging design.

To make it easier, we have a complete guide for you on how to design your dielines with Pacdora.

The only time you should be using a rasterized file is if it’s a photographic image. This is because they need the individual pixels to replicate real-life images being captured.

For optimal quality, ensure that the resolution is set to 300 DPI.

10. Prototyping

Before going into full production with your custom product, you can request a prototype to test out the design. This is especially important for larger orders, to avoid any design, spelling or printing errors.

11. Production and Shipping

Once you’re done with all of the paperwork, your product’s packaging is good to go for mass production! Depending on a few different factors such as your requested timeline, the size of the order, and the delivery method, it’ll take some time for your shipment to arrive. But don’t worry, you’ll be kept in the loop by your account manager who will make sure that you’re always on track with the progress of your order.

Congratulations on making it to the product packaging stage!

This guide walked you through everything you need to do to streamline the process. If you want to design your product packaging without hassle then you can try Pacdora, an Online 3D packaging design tool.

Leave a comment